The Impact of Warehousing Automation on the Supply Chain: A Comprehensive Overview

Warehouse automation has become more popular recently. Manual operations can lead to errors, delays, inefficiencies, decreased productivity, and reduced profits. This can cause dissatisfaction among business partners and customers. Automation can involve various technologies, such as autonomous vehicles and robots or software. The best approach is likely a combination of these technologies.

Full automation involves various processes and functions, including automatic data entry and storage, as well as goods delivery. This warehouse automation guide dives into the main layers of automation, including basics, hardware and software solutions, their advantages, and real-life case studies for reference.

Building the Future: An Introduction to Warehouse Automation

Warehouse automation focuses on identifying repetitive tasks and creating automated solutions for them. Modern warehouses are equipped with various technologies to streamline tasks such as data entry, picking, storing, and shipping of goods.

The success of retail companies is greatly influenced by their ability to create efficient supply chains and reduce costs and expenses. Achieving this can be facilitated by utilizing warehouse management automation to streamline key operations. Common features of these systems can include inventory and back-office management, picking and delivery, barcode scanning, and handling charges.

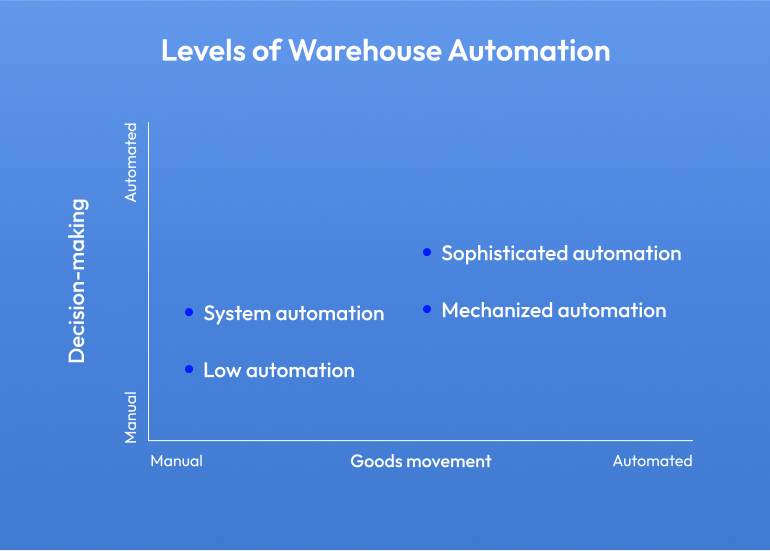

Currently, four layers of automated warehouse management have been identified.

There are various automation solutions to choose from, which will be further discussed soon. When choosing automated warehouse software, it’s important to consider the company’s current situation, future goals, and financial limitations. These solutions are closely tied to logistics, a complex area that requires expertise and time. To achieve the best results, it’s advised to select a software development company with experience in warehouse automation.

The Hidden Advantages of Implementing Automated Technology in Warehousing

The warehouse management software provides full coverage of all order lifecycle stages. Understanding the impact of automation on different warehouse processes is essential. Let’s find out further.

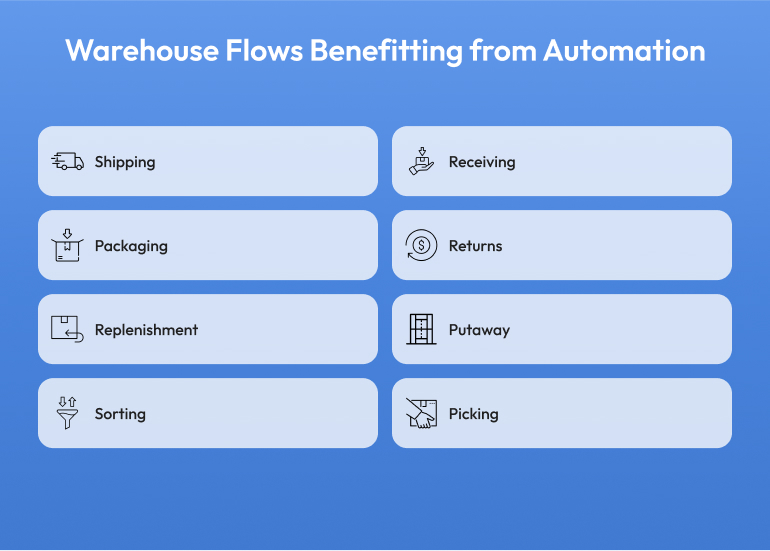

Receiving. Smartphones are used to collect data for goods receiving processes. Integrated software enables managers to efficiently manage and store information critical to warehouse operations and automation workflows.

Returns can be automated through the use of autonomous vehicles such as lifters or conveyors. Automated warehouse technology can be utilized for sorting items, restocking shelves, or placing inventory in designated storage areas.

Putaway. Products move from “receiving” to “storage” during the putaway process, helping to streamline cross-docking operations and expedite the transfer of freight from inbound to outbound trucks without warehouse storage.

Picking. Manual package picking results in increased expenses. Warehouses can improve efficiency by implementing automation solutions. Operators dedicate approximately 50% of their working hours to traveling within the warehouse. The use of mobile robots can increase freight delivery speed by efficiently transporting goods to meet customer orders.

Sorting. Operators devote significant time and effort towards sorting and consolidating inventory, which could be automated. Warehouse automation technology, such as AS/RS systems, improves stock control and quality monitoring by efficiently managing small stocks individually.

Replenishment. The WMS system automatically creates a dispatch request when stock levels reach the nominal level. Automating restocking procedures saves money by preventing excess inventory and loss.

Packaging. The packaging automation system uses algorithms to select the most appropriate freight packaging based on factors such as product size, durability, and material expenses. The automated warehouse management system considers the environmental impact of materials as well.

Shipping. Through the use of warehouse equipment, modern technology, and mobile apps, transportation organizations can effectively handle carriers, calculate freight costs, and tag packages for shipment.

Advantages of Automation in Warehousing

The implementation of automation in warehouse processes can offer numerous advantages to logistics companies, such as improved efficiency and decreased incidents of human errors. We’ll explore the key benefits of implementing warehouse automation.

Enhanced security

Warehouse automation software facilitates the movement of products to managers. This leads to a reduction in the number of employees and equipment in the facility, enhancing the overall safety of the automated warehouse processes.

Maximizing space efficiency

Warehouse systems utilize automated guided vehicles to efficiently manage product storage and retrieval, maximizing space optimization. AS/RS systems utilize conveyors to reduce the need for extensive aisle space.

Getting faster

The use of various technologies in warehouse automation helps operators efficiently locate items. By combining WMS with advanced technology, transportation companies can streamline tasks like order fulfillment and inventory accounting, leading to increased productivity and efficiency among employees.

Inventory Optimization

Automation in warehouses is proven to reduce human error, enhance inventory control, and provide precise inventory counts and data. To improve inventory management, it is recommended to use logistics software from a reliable vendor.

Addressing Challenges in Warehouse Automation

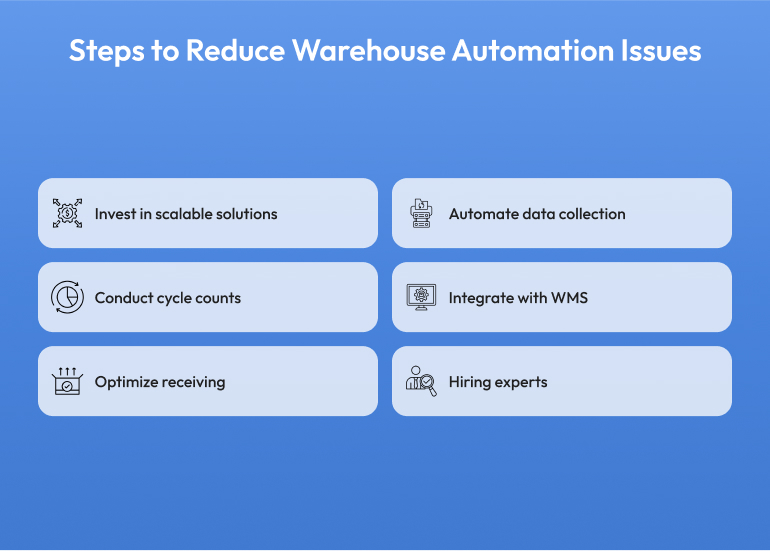

Automation solutions have the potential to benefit logistics businesses, although caution should be exercised to avoid potential issues. Setting up and running a system requires investments, expertise, and skilled personnel. Equipment failure can lead to downtime and repair expenses.

Implementing warehouse automation best practices is the most effective way to tackle those challenges. Below are some examples of successful implementations.

Wrapping Up

We have outlined only the basics of warehousing automation. To know more, you can contact the skilled logistics software building provider. The provider’s specialists will guide you through the intricacies of warehousing automation, offering tailored solutions and expert insights to optimize your logistics operations and drive efficiency gains throughout your supply chain.